Design and Engineering

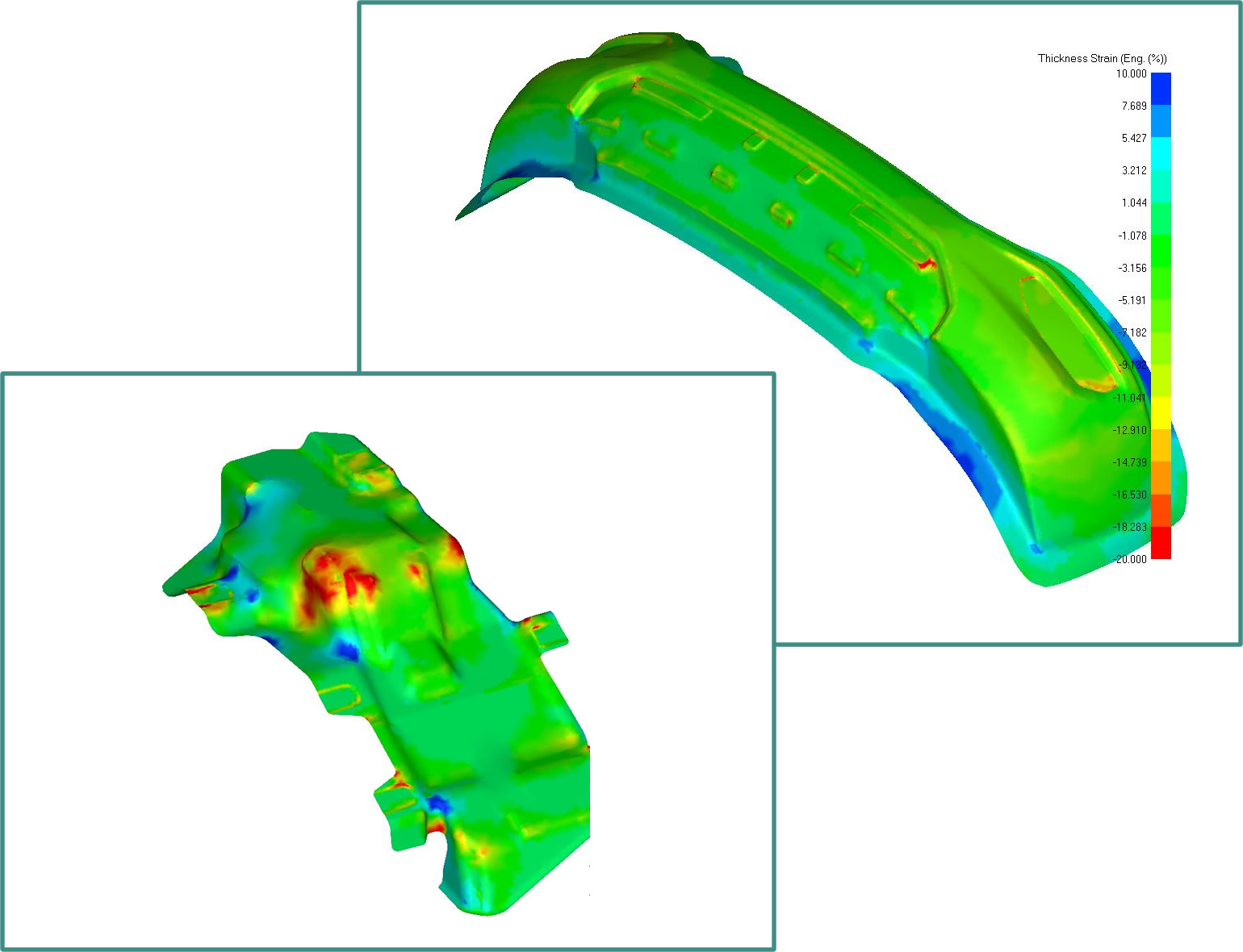

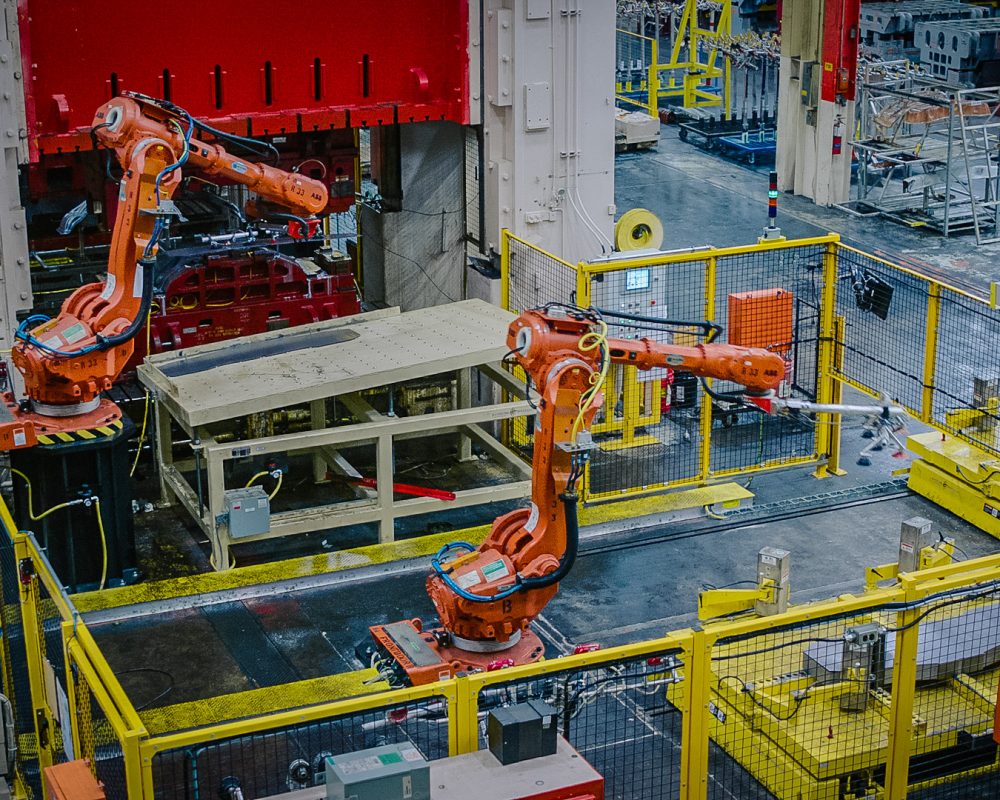

Experts in Advanced Engineering & Innovation, AGS has made significant investments in advancing its engineering, design and research and development capabilities over the past several years. These innovations have enabled AGS to become a leader in a variety of areas surrounding quality, lightweighting, corrosion resistance and material reduction.

Where we excel

- Full Service, and Advanced Bumper Design

- Lightweighting & Multi-Materials

- Tooling

- Analytical Modeling and 3D Printing

- Benchmarking

- R&D Capabilities in chrome plating

- In-house testing

- Launch Support